#Linear encoder technologies

Explore tagged Tumblr posts

Note

Just wanted to share this factoid with you (I’ve been a tour stagehand)

The “Roomba” is called a Mobilator in the industry. Touring stages on the highest end like Taylor’s is designed and manufactured to scale by a company in the industry called TAIT Towers out of Lititz, PA. (They’ve been on the cutting edge of stage design)

“The TAIT Mobilator is a stage technology that provides linear motion to set pieces and stage wagons. It can move up to 12,500 lbs (5,669.9 kg) and can be used with multiple stage elements to create moving applications”

“Control: The Mobilator can be controlled locally or by TAIT Navigator when paired with TAIT smart air compressors and encoders.”

The more you know ☺️ ... thank you!

20 notes

·

View notes

Text

"The ideology of Silicon Valley is clear: move fast and break things, scale at all costs, pump and dump. The lingering earth-flavored utopianism of the California Ideology softened the edge, and American two-party politics ensured at least a facade of responsibility, but both have largely fallen away over the past year.

I can point to Musk’s acquisition of Twitter, tech company layoffs, general societal Jokerfication post-Covid and the takeoff of generative AI as proximate causes, but the root cause is an unsustainable concentration of power among frustrated young men; more specifically, among engineers.1

C.P. Snow famously described the cleavage between The Two Cultures in Western society, between science and the humanities. In 1959, Snow observed the social supremacy of the humanities—his argument was that they needed to learn to understand the other culture, for the benefit of society.

But now the engineers are in charge. Universities are STEM departments and professional schools, with humanities a luxury curiosity. Television and now social media has devastated literary culture. We no longer believe in the rule of law or in liberalism more broadly.

So now they’re openly talking about Accelerationism, “effective accelerationism,” even, leaping into the gaping hole in vibe space left by the implosion of FTX/Effective Altruism. Venture capitalist Marc Andreessen has been pushing this for many months, and yesterday released

“The Techno-Optimist Manifesto”

The content is far too stupid to engage with; it takes 10x the effort to refute bullshit than to produce it. Instead, we should think about this document as post-textual. The medium is natural language, but what it encodes is not linear, conceptual reason but vibes. The concluding list of thinkers and fictional characters is simply a clout bomb.

This is a collection of tweets: pure discourse, responding to The Discourse that came before it. In contrast to the idea of individual agency at the heart of liberalism, there is no agency here: the writing is driven entirely by discourse and vibes. It is all implied by what came before it. None of means anything."

[...]

"But Andreessen is more interested in the right hand of cybernetics—he specifically and repeatedly endorses the philosophy of Nick Land, the most famous proponent of Accelerationism. I can’t believe it’s come to this.

Thiel famously said that capitalism and democracy are incompatible, and chose the former.

Land’s Accelerationism says that (techno)capitalism and humanity are incompatible, and yet he still chose the former.3

So make no mistake. Accelerationism is terrorism.4 It violates what Ortega y Gasset calls “man’s most fundamental right...the right to continuity.” Technological accelerationism aims to eliminate the human and instantiate the world of the inhuman functionary. The current rate of change is already incompatible with human dignity, and they want to speed it up. From the manifesto:

We believe in accelerationism – the conscious and deliberate propulsion of technological development – to ensure the fulfillment of the Law of Accelerating Returns.

For people who valorize “The Scientific Method,” they don’t seem to understand what a “Law” is. If this is a Law of Nature, it’s odd that humans have to “fulfill” it. If it’s a human Law, who passed it? Can we overturn it?"

4 notes

·

View notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1��, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

High-Performance Digital Display for Draw Wire Encoder

Experience accurate linear displacement measurement with Briter's draw wire encoder digital display. This intuitive device showcases real-time data on absolute position and stretching speed of RS485/CAN draw wire encoders. Ideal for industrial applications requiring precise position sensing over a range of 0-10 meters, this reliable technology ensures seamless integration for enhanced efficiency and productivity. Simplify your linear displacement sensor needs with this sophisticated digital display that offers clear and concise data visualization. Explore the power of advanced measurement with Briter's draw wire encoder solution today at briterencoder.com.

0 notes

Text

HAAS Brushless Servo Motor: Ultimate Choice For CNC Performance

In today’s manufacturing world, where precision, speed, and reliability determine competitive edge, the machinery behind production lines plays a critical role. CNC machines have become the backbone of modern fabrication, relied upon by industries ranging from aerospace to automotive. At the heart of many CNC systems lies the servo motor, responsible for accurate motion control, speed regulation, and torque management.

As technological standards rise, more workshops and manufacturers are shifting toward brushless servo motors for better performance and lower maintenance demands. With brands like HAAS leading the way, the integration of advanced motors is no longer optional; it's essential.

HAAS Brushless Servo Motor

A servo motor is a key component of CNC machines, controlling precise linear or rotational movement. Unlike brushed motors, which rely on physical brushes to transmit current, brushless servo motors operate electronically. This not only reduces wear but also improves efficiency and performance over time.

The HAAS Brushless Servo Motor stands out for its engineering precision and reliable performance under continuous operational stress. These motors are designed for machines that require fine-tuned control and consistent operation, delivering responsive movement without overheating or stalling.

Features of HAAS Brushless Servo Motors

Superior Torque and Speed Control These motors deliver high torque at variable speeds, allowing CNC machines to maintain accuracy even during high-load tasks.

Maintenance-Free OperationWithout brushes to replace, wear and tear are minimized, saving businesses time and money on repairs and downtime.

High Efficiency and Low Heat OutputBrushless motors are more efficient, meaning they convert more energy into motion, reducing energy costs and improving overall system performance.

Advanced Feedback SystemsIntegrated encoders and sensors enable real-time feedback, helping systems adjust instantly to maintain exact positioning.

Benefits for CNC Workshops and Manufacturers

Investing in a HAAS Brushless Servo Motor offers multiple long-term advantages:

Consistent Machining Accuracy: Perfect for applications that require detailed and repetitive cuts. Extended Lifespan: Less friction and lower maintenance mean longer operational life. Operational Savings: Reduced maintenance, lower energy consumption, and fewer part replacements help improve bottom-line efficiency. Higher Productivity: Faster cycle times and fewer disruptions translate to better output with fewer resources.

Industries That Rely on HAAS Servo Motors

From precision metal fabrication shops to full-scale industrial production plants, businesses rely on the power and reliability of HAAS components. Applications include:

CNC milling and turning centers

Robotics and automation systems

Aerospace and defense manufacturing

Automotive parts production

For example, small-to-midsize workshops have benefited from upgrading legacy motors to modern brushless options, achieving faster production with minimal reinvestment.

Choose Refurbished HAAS Brushless Servo Motors

While brand-new equipment offers cutting-edge technology, refurbished motors present an excellent balance of performance and affordability.

Purchasing a HAAS Brushless Servo Motor in refurbished condition can provide:

Significant cost savings

Verified performance with professional testing

Quick availability compared to long lead times for new units

Environmentally conscious purchasing by reducing industrial waste

However, it’s important to source these parts from trusted suppliers to ensure quality and reliability.

Final Thoughts

For manufacturers looking to elevate their CNC systems' efficiency, accuracy, and reliability, the HAAS Brushless Servo Motor is a smart investment. Its combination of high-performance engineering, minimal maintenance, and adaptability to various applications makes it a top choice for modern production environments.

Explore reliable, performance-tested options available now. Visit CNC TOOLS LLC to view refurbished HAAS servo motors and upgrade your system with confidence.

0 notes

Text

Barcode Definitions 101 | Uses & Guide | AIDC INDIA – 2025

Barcodes play a vital role in today’s business environment. From retail checkout systems to inventory tracking, they have transformed the way data is collected and managed. As we step into 2025, it becomes more important to understand barcode definitions and their role in modern operations. This guide from AIDC Technologies India is designed to simplify everything you need to know about barcodes and their practical uses.

2. What Is a Barcode? A Simple Definition Explained

A barcode is a machine-readable code represented as numbers and parallel lines or squares. Barcode definitions explain how this code is structured and what type of data it holds. Barcodes typically encode product information like SKU, batch number, or manufacturing details. They are scanned using barcode readers, which instantly convert visual patterns into digital data.

3. Types of Barcodes Used in 2025

There are various types of barcodes in use, each with its own format and function. Barcode definitions help identify which format suits a particular industry or task:

1D Barcodes: These are linear barcodes like UPC, EAN, and Code 128, often used in retail and inventory.

2D Barcodes: These include QR codes and Data Matrix codes, used for storing more complex data.

PDF417: A stacked linear barcode used on IDs and transport documents.

Each format has a specific barcode definition and is designed to meet unique requirements based on space, readability, and data needs.

4. How Barcodes Work: From Scanning to Data Collection

The basic process begins with printing a barcode on a label or product. A barcode scanner reads the lines or squares, and decoding software extracts the stored information. Barcode definitions help determine what type of scanner and software are needed to read the code accurately. This simple process eliminates manual entry and ensures fast, reliable data capture across operations.

5. Key Uses of Barcodes in Modern Industries

Barcode definitions are foundational in a wide range of sectors. In retail, barcodes are used for pricing and checkout. In warehouses, they track stock movement and inventory levels. Healthcare uses barcodes for labeling medicine and managing patient records. Logistics companies depend on barcodes for real-time tracking of shipments. The correct use of barcode definitions ensures that the data captured is accurate and usable.

6. AIDC India’s Role in Barcode Solutions

AIDC Technologies India provides complete barcode systems—from labels and scanners to printers and integration software. Our deep understanding of barcode definitions allows us to recommend the right type of barcode solution for your specific industry. We support clients in retail, manufacturing, healthcare, education, and logistics with customized systems that improve data tracking and minimize errors.

7. Benefits of Using Barcodes in Business

Barcodes offer several benefits that go beyond just automation. Proper use of barcode definitions brings improvements in many business areas:

Speed: Barcodes speed up scanning and reduce checkout time.

Accuracy: Minimizes manual errors in data entry.

Inventory Control: Keeps track of stock movement in real time.

Cost Savings: Reduces labor and improves efficiency.

By applying the right barcode definitions, businesses can unlock these advantages more effectively.

8. Barcode Definitions vs QR Codes vs RFID

Understanding how barcode definitions compare to other technologies helps in selecting the best system. Barcodes are simpler and more cost-effective for small to medium-sized operations. QR codes, which are 2D barcodes, can store more data and are often used in mobile marketing or payment systems. RFID, which uses radio waves, allows item tracking without line-of-sight scanning. However, barcode systems remain more accessible and easier to implement.

9. Smart Barcode Scanning Solutions by AIDC India

AIDC India offers barcode scanning devices that are optimized to read all standard barcode definitions. Whether it’s a handheld scanner for retail or an industrial-grade scanner for warehouses, our devices ensure fast, accurate, and error-free data collection. We also provide software tools that integrate these scanners with your inventory or billing systems for seamless workflows.

10. Choosing the Right Barcode System for Your Business

Barcode definitions help businesses choose the right format, printing method, and scanning tools. AIDC India helps you evaluate your operational needs, the volume of data you need to encode, and the environment where scanning takes place. Based on these factors, we recommend and implement barcode systems that align with your goals.

11. Future of Barcodes: Trends to Watch in 2025

As we look ahead, barcode definitions are evolving with technology. Mobile barcode scanning is becoming more popular, especially in e-commerce and delivery services. Smart inventory systems are using AI to analyze barcode data for forecasting and planning. Environment-friendly printing solutions are also emerging. AIDC India stays updated with these trends to provide future-ready barcode solutions for businesses of all sizes.

12. Get Started with Barcode Solutions from AIDC India

Barcodes are a small but powerful part of your business infrastructure. With the right barcode definitions and tools, you can automate operations, reduce costs, and improve customer satisfaction. AIDC Technologies India offers everything you need—from barcode labels and printers to scanners and integration support.

Call to Action: Ready to streamline your operations with smart barcode solutions? Contact AIDC Technologies India today for a free consultation, customized recommendations, and reliable tools that match your business goals.

#BarcodeDefinitions2025#BarcodeGuide#BarcodeUses#AIDCIndiaBarcode#BarcodeTechnology#SmartTrackingSolutions#BarcodeBasics#InventoryManagement#BarcodeScanning#RetailTech2025

0 notes

Text

0 notes

Text

Precision in Motion: The Importance of Linear Position Sensors in Hydraulic Cylinders

In hydraulic systems, power is nothing without control. Whether it’s lifting, pushing, or positioning, the ability to monitor the exact location of a cylinder’s piston rod can be the difference between smooth operation and costly inefficiency. That’s where linear position sensors come in—a technology that has become essential in applications demanding real-time feedback, safety, and motion accuracy.

At THM Huade, we understand that for today’s machinery to perform at its best, it must also think—monitoring itself and adjusting on the fly. Integrating linear position sensors into hydraulic cylinders is one of the most effective ways to achieve this.

What Does a Linear Position Sensor Actually Do?

A linear position sensor is designed to measure the position of a piston or rod within a hydraulic cylinder and transmit that data to a controller or interface. This allows a system to “know” exactly where the rod is in its stroke—helping manage speed, force, and response in real-time.

These sensors come in a range of formats, including:

Magnetostrictive sensors for high precision and durability

Potentiometric sensors for cost-sensitive applications

Inductive and LVDT types for rugged, contactless performance

Regardless of the technology, the goal is the same: deliver continuous, accurate position feedback under tough industrial conditions.

Why Hydraulic Systems Need Real-Time Position Sensing

Hydraulic cylinders are workhorses. They generate immense force and are used in everything from heavy construction to aerospace. But without position sensing, they’re effectively “blind”—relying only on pressure changes or end-limit switches for control.

Here’s how linear position sensors add value:

Improved accuracy in stroke movement

Feedback for automated or closed-loop systems

Enhanced safety with position-aware operations

Reduced downtime via diagnostics and predictive maintenance

Energy savings by optimizing fluid delivery to actual load requirements

For OEMs and system designers, adding a sensor turns a standard hydraulic cylinder into a smart actuator, capable of adapting to changing loads, sequences, and safety logic.

Built to Endure: Sensor Technology from THM Huade

THM Huade offers sensor-integrated hydraulic solutions built for industries where failure is not an option. Our sensors are designed for:

Shock and vibration resistance in off-road and industrial settings

IP-rated protection against dust, water, and extreme temperatures

Long service life, with solid-state and contactless options for minimal wear

We work closely with OEMs to embed these sensors directly into the cylinder housing or mount them externally, depending on system requirements and maintenance preferences.

Use Cases: From Automation to Heavy Machinery

The adoption of linear position sensors is growing rapidly in:

Agricultural machinery (e.g., smart tractors, sprayers)

Construction equipment (e.g., excavators, cranes, lifts)

Industrial automation (e.g., material handling, robotic arms)

Energy and marine sectors (e.g., dam gates, drilling platforms)

In each application, precise position feedback helps operators and systems execute movements more efficiently, safely, and reliably.

The Future: Smart Hydraulics and Industry 4.0

As machines become more intelligent, the demand for real-time feedback loops grows. Position sensors play a central role in enabling predictive maintenance, adaptive controls, and remote diagnostics—pillars of Industry 4.0.

At THM Huade, we’re not just building components; we’re engineering intelligent hydraulic solutions that fit seamlessly into the future of connected machinery.

Upgrade your hydraulics with smart sensing. Learn more about linear position sensor solutions from THM Huade.

#LinearPositionSensor#HydraulicCylinders#SmartHydraulics#IndustrialSensors#AutomationEngineering#THMHuade#MotionControl#HydraulicSolutions#PrecisionInMotion

0 notes

Text

7 Skills You'll Build in Top AI Certification Courses

You're considering AI certification courses to advance your career, but what exactly will you learn? These programs pack tremendous value by teaching practical skills that translate directly to real-world applications. Let's explore the seven key capabilities you'll develop through quality AI certification courses.

1. Machine Learning Fundamentals

Your journey begins with understanding how machines learn from data. You'll master supervised and unsupervised learning techniques, working with algorithms like linear regression, decision trees, and clustering methods. These foundational concepts form the backbone of AI systems, and you'll practice implementing them through hands-on projects that simulate actual business scenarios.

2. Deep Learning and Neural Networks

Building on machine learning basics, you will dive into neural networks and deep learning architectures. You will construct and train models using frameworks like TensorFlow and PyTorch, understanding how layers, activation functions, and backpropagation work together. Through AI certification courses, you will gain confidence working with convolutional neural networks for image processing and recurrent neural networks for sequential data.

3. Natural Language Processing (NLP)

You will develop skills to make computers understand and generate human language. This includes text preprocessing, sentiment analysis, named entity recognition, and building chatbots. You'll work with transformer models and learn how technologies like GPT and BERT revolutionize language understanding. These NLP skills are increasingly valuable as businesses seek to automate customer service and content analysis.

4. Data Preprocessing and Feature Engineering

Raw data rarely comes ready for AI models. You'll learn to clean, transform, and prepare datasets effectively. This includes handling missing values, encoding categorical variables, scaling features, and creating new meaningful features from existing data. You'll understand why data scientists spend 80% of their time on data preparation and master techniques to streamline this crucial process.

5. Model Evaluation and Optimization

Creating an AI model is just the beginning. You'll learn to evaluate model performance using metrics like accuracy, precision, recall, and F1-score. You'll master techniques for preventing overfitting, including cross-validation, regularization, and dropout. AI certification courses teach you to fine-tune hyperparameters and optimize models for production environments, ensuring your solutions perform reliably in real-world conditions.

6. Ethical AI and Responsible Development

You'll explore the critical aspects of AI ethics, including bias detection and mitigation, fairness in algorithms, and privacy considerations. You'll learn frameworks for responsible AI development and understand regulatory requirements like GDPR's right to explanation. This knowledge positions you as a thoughtful practitioner who can navigate the complex ethical landscape of artificial intelligence.

7. AI Deployment and MLOps

Finally, you'll bridge the gap between development and production. You'll learn to deploy models using cloud platforms, create APIs for model serving, and implement monitoring systems to track performance over time. You'll understand containerization with Docker, orchestration with Kubernetes, and continuous integration/continuous deployment (CI/CD) pipelines for machine learning projects.

Conclusion

These seven skills represent a comprehensive toolkit for AI practitioners. The best AI certification courses combine theoretical knowledge with practical application, ensuring you can immediately apply what you've learned.

As you progress through your chosen program, you'll notice how these skills interconnect – from data preprocessing through model development to ethical deployment. This holistic understanding distinguishes certified AI professionals and provides the foundation for a successful career in artificial intelligence.

For more information, visit: https://www.ascendientlearning.com/it-training/vmware

0 notes

Text

Whispers of the Universe: Decoding the Power of Angel Time 1111

In a world dominated by digital distractions and fleeting trends, there exists a persistent symbol that transcends time, logic, and linear thought: angel time 1111. It’s more than a repeated numerical coincidence—it’s a metaphysical mirror held up by the universe, reflecting our inner alignment and spiritual readiness. When 11:11 appears, many dismiss it as mere chance. But those attuned to deeper consciousness know that it signals an awakening. It’s an invitation to pause, reflect, and realign. The question is: Are we truly listening?

To navigate the abstract wisdom of 1111, there now exists a breakthrough software—a technological companion that transforms mystical insight into actionable clarity. This article illuminates how such a tool deciphers the cryptic elegance of angel time by fusing analytical intelligence with spiritual resonance.

The Digital Echo of a Divine Signal

Why does the recurrence of 1111 captivate the psyche so profoundly? Because it’s not just a number—it’s an encoded cosmic nudge. It appears during pivotal transitions, emotional turmoil, or spiritual breakthroughs. Many believe it's the universe's way of whispering: You are on the right path. But understanding this divine frequency requires more than intuition.

This is where cutting-edge software emerges as a modern oracle, translating the sacred symbolism of 1111 into structured, intelligible insights. Rooted in artificial intelligence and emotional analytics, the software doesn’t reduce the experience to cold data; it elevates it. By analyzing behavioral, temporal, and emotional cues surrounding every 1111 encounter, it provides a reflective lens through which users can interpret their inner evolution.

From Synchronicity to Strategy: How the Software Works

Designed with intuitive architecture and emotional sensitivity, this software goes far beyond mere time-stamp tracking. It encapsulates an entire ecosystem of functionality, built to amplify human potential by decoding spiritual patterns. Its primary features include:

Chrono-Spiritual Mapping: Tracks the time, date, and location of 1111 sightings and aligns them with the user’s cognitive-emotional state.

Emotive Correlation Engine: Uses biometric signals and journaling behavior to map emotional intensity during 1111 appearances.

Pattern Insight Dashboard: Reveals long-term trends, emotional cycles, and synchronicity hotspots.

Guided Introspection Prompts: Offers real-time reflections and journal prompts that contextualize the moment of 1111, fostering intentional action.

Energy Calibration Alerts: Notifies users of repetitive misalignments or patterns requiring introspective attention.

Its specs reflect high-performance efficiency: encrypted personal data management, cross-platform adaptability, low-latency data syncing, and a neural-adaptive learning model that evolves with user behavior. In essence, it is a digital sage—silently observing, intuitively guiding.

The Philosophical Weight of Angel Time

To understand 1111 time is to confront one's truth. It is a symbol that transcends languages, belief systems, and cultures. Its symmetrical structure speaks of balance, duality, and infinite possibility. Appearing when least expected but most needed, it encourages mindfulness and reminds us of our inner architect—the one designing our future through present awareness.

Integrating this sacred awareness into daily life is no easy feat. That is precisely why the software plays a pivotal role: it does not mystify the experience; it clarifies it. Instead of allowing these divine signals to drift by unnoticed, it captures, contextualizes, and codifies them into meaningful guidance. It becomes both mirror and mentor—honoring the spiritual while leveraging the rational.

Why This Software Matters in an Age of Overwhelm

In today’s hyper-connected existence, moments of stillness are rare. Signals like angel time often go unnoticed, lost in a barrage of notifications and schedules. This is the cost of modernity. But technology, when rightly employed, can become a vessel of transcendence.

This software offers not escape, but empowerment. It doesn’t claim to replace intuition—it enhances it. Through systematic tracking and interpretive analysis, it encourages users to slow down, notice patterns, and extract wisdom from the seemingly mundane. And in doing so, it cultivates a habit of self-awareness, emotional fluency, and conscious decision-making.

You can also watch: Apne jeevan ka rasta saaf karein AstroLive ke saath!

youtube

Conclusion: Listening When the Universe Speaks

To encounter angel time 1111 is to be called—subtly, yet persistently—toward one's higher path. It is a quiet invitation to remember, to awaken, and to align. And now, in an era where intuition often battles with information overload, this sophisticated software offers a way to honor both.

It transforms fleeting moments of synchronicity into structured reflections. It maps ethereal experiences onto a digital canvas. And most importantly, it reminds us that even in a mechanized world, the universe still speaks—if only we have the tools to truly listen.

1 note

·

View note

Text

Automated Production and Testing Processes of Rocker Switches

1. Introduction

With the rapid development of industrial automation, the manufacturing process of rocker switches has undergone a transformation from traditional manual production to highly automated, precision-controlled production lines. This shift not only improves production efficiency and product consistency but also enhances the competitiveness of enterprises in the market. This article will provide a comprehensive overview of the automated production and testing processes of rocker switches, including automated terminal insertion, automated spot welding, automated LED placement, as well as contact resistance testing, travel and pressure testing, continuity time measurement, and industrial vision-based appearance inspection. These technologies represent a high degree of integration between mechanical systems, electronic control, and intelligent algorithms.

2. Automated Assembly Processes in Rocker Switch Production

2.1 Automated Terminal Insertion

Terminal insertion is one of the most critical steps in rocker switch production. Traditional manual insertion is prone to positional deviation and insertion force instability, which may cause defective contact or product rejection. Modern production lines adopt servo-controlled automated terminal insertion systems, which use multi-axis manipulators to position terminals precisely. High-precision optical sensors ensure insertion depth and orientation consistency.

For instance, the system automatically picks the copper terminal from the feeder, precisely aligns it with the switch base, and inserts it at a controlled speed and pressure. This ensures the mechanical integrity of the assembly and avoids micro-damage to the plastic shell, laying a solid foundation for subsequent spot welding.

2.2 Automated Spot Welding

Spot welding ensures the electrical connection between terminals and leads. The automated welding station uses resistance spot welding controlled by pulse current and time curves to precisely fuse metal interfaces.

Advanced systems are equipped with closed-loop current monitoring and displacement sensors, allowing real-time compensation for contact surface changes, thus ensuring stable and low-resistance welded joints. Additionally, the system is integrated with fume extraction and safety monitoring modules, improving the working environment and overall safety.

2.3 Automated LED Placement

Rocker switches with indicator lights require precise LED placement. Automated LED placement machines use high-speed pick-and-place heads and machine vision calibration to accurately position the LED within the switch cavity. The polarity and brightness are verified in real time during the process to ensure optical performance and visual consistency.

This process ensures that the LED does not shift during encapsulation or welding, maintaining long-term reliability and aesthetic appeal of the final product.

3. Automated Testing Systems for Rocker Switches

To ensure product reliability, each rocker switch must undergo comprehensive electrical and mechanical performance tests before leaving the factory.

3.1 Contact Resistance Test

The contact resistance test evaluates the resistance value across the conductive path under rated pressure. Modern automated testing equipment uses a 4-wire Kelvin method to eliminate lead resistance influence. The system can test multiple switches simultaneously, display resistance distribution curves in real-time, and automatically classify unqualified products.

Typical requirement: contact resistance < 50 mΩ (depending on the application scenario).

3.2 Travel and Pressure Test

Travel and pressure tests ensure the rocker switch provides the correct tactile feedback. High-precision linear actuators simulate human finger pressing motion, while pressure sensors and displacement encoders collect force-displacement data.

This allows evaluation of stroke range (e.g., 1.8–2.5 mm), actuation force (e.g., 300–600 gf), and pressing smoothness. Abnormalities such as mechanical jamming, misalignment, or inconsistent feedback can be identified and rejected automatically.

3.3 Continuity Time Measurement

Continuity time refers to the response speed of the switch after actuation. The test system uses high-speed data acquisition cards to detect signal transition points and calculate the time difference between actuation and circuit conduction.

This indicator is especially important for automotive and industrial control applications, where millisecond-level response times are required.

4. Visual Inspection and Intelligent Defect Detection

4.1 Industrial Vision System Introduction

Visual inspection replaces traditional manual quality checks, using high-resolution cameras, lighting modules, and image recognition algorithms to inspect every rocker switch.

It can detect:

Missing parts

Scratches or deformation on the housing

Logo misalignment or blurring

Incorrect assembly (e.g., misaligned rockers, LED offset)

4.2 High Efficiency and Accuracy

For example, a dual-camera system combined with a rotary conveyor can inspect 120 pieces per minute. The system achieves a detection accuracy of 0.05 mm, capable of identifying minute cracks or flash edges on plastic parts.

Deep learning algorithms further enhance recognition ability by learning from real production defects, continuously optimizing detection logic.

5. Traceability and Data Integration

All testing data and inspection results are integrated into the MES (Manufacturing Execution System), enabling full traceability. This helps:

Identify root causes of quality issues quickly

Analyze yield trends

Refine production parameters in real time

By applying barcode/QR code identification to each unit, data from insertion, welding, testing, and inspection can be correlated with the specific product batch, greatly enhancing quality control and accountability.

6. Conclusion

The automated production and testing processes of rocker switches represent the future trend of smart manufacturing in the electromechanical components industry. From terminal insertion to visual inspection, each step is carefully controlled and monitored, improving production efficiency, product quality, and cost-effectiveness. With continued development in industrial AI and robotics, the production of rocker switches will become even more intelligent, flexible, and scalable, helping enterprises meet the diverse and demanding needs of global markets.

en.dghongju.com

0 notes

Text

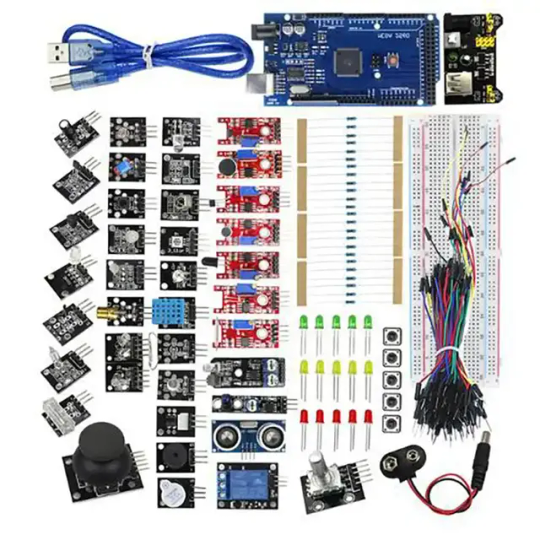

Stem Education for Arduino Mega Kit Atmega2560 MCU with Sensor Modules The Arduino Mega Kit electronic components packing list below: - 1 x KY-006 passive buzzer module - 1 x two colors module - 1 x Hit sensor module - 1 x Vibration switch module - 1 x Photo Resistance Module - 1 x Key switch module - 1 x Tilt switch module - 1 x 3-color full-color LED SMD modules - 1 x Infrared emission sensor module - 1 x 3-color LED module - 1 x Mercury open optical module - 1 x Yin Yi 2-color LED module 3 MM - 1 x active zoomer module - 1 x temperature sensor module - 1 x Automatic flashing colorful module - 1 x Mini reed magnetic modules - 1 x Hall magnetic sensor module - 1 x Infrared receiver sensor module - 1 x Class sensor magnetic Bihor - 1 x Magic Cup Light Module - 1 x encoder module - 1 x Broken Optical Module - 1 x Heartbeat Detection Module - 1 x Reed module - 1 x Obstacle avoidance sensor module - 1 x sensor module - 1 x Microphone sound sensor module - 1 x Laser sensor module - 1x5 V relay module - 1 x temperature sensor module - 1 x temperature sensor module - 1 x Linear Magnetic Salon Sensors - 1 x Flame sensor module - 1 x Sensitive Microphone Sensor Module - 1 x Temperature and humidity sensor module - 1 x XY-like joystick module - 1 x Metal Touch Sensor Module - 1x Development Board for Arduino Mega 2560 R3 - 1 x SR04 - 1 x MB-102 - 1x9v battery buckle - 1 x Bread plate electric source - 6x1 K - 6x10 K - 6x100 K - 6 x 220R - 5 x keys - 4 x LED yellow 5mm - 4 x LED Red 5mm - 4 x LED Green 5mm The atmega2560 mcu development board for arduino mega kit comes with exact parts list as piture show online. Note:We only provide hardware.Turtial or lesson is not provided,they are universal use everywhere from the internet. Other development kits,view here. If you are STEM education user,welcome contact us to talk the customzied hardware list. About Us: Shenzhen Chengsuchuang Technology Co.,Ltd. provide one stop supply solution to Arduino development board kits,including arduino uno,mega,nano etc.All of our products warranty is 1 year warranty default.We are in the electronics hardware since 2014. Read the full article

0 notes

Text

High-Performance Digital Display for Draw Wire Encoder

Experience accurate linear displacement measurement with Briter's draw wire encoder digital display. This intuitive device showcases real-time data on absolute position and stretching speed of RS485/CAN draw wire encoders. Ideal for industrial applications requiring precise position sensing over a range of 0-10 meters, this reliable technology ensures seamless integration for enhanced efficiency and productivity. Simplify your linear displacement sensor needs with this sophisticated digital display that offers clear and concise data visualization. Explore the power of advanced measurement with Briter's draw wire encoder solution today at briterencoder.com.

0 notes

Text

Phage Display Services: Accelerate Your Peptide Discovery with KS-V Peptide

In the world of modern drug development and molecular diagnostics, phage display technology has become a powerful tool for identifying high-affinity peptide ligands, antibodies, and proteins. At KS-V Peptide, we provide end-to-end phage display services to help researchers and biotech companies uncover novel therapeutic candidates with speed and precision.

What is Phage Display?

Phage display is a molecular technique that uses bacteriophages to connect proteins with the genetic information that encodes them. This method allows for high-throughput screening of peptide or protein libraries to discover molecules that bind to a target of interest, such as a receptor, enzyme, or disease marker.

Why Choose KS-V Peptide’s Phage Display Platform?

At KS-V Peptide, our phage display platform is built on deep expertise and advanced infrastructure. We offer:

✅ Diverse peptide libraries including linear, cyclic, and customized libraries

✅ High-throughput screening and panning against a wide range of targets

✅ Expert bioinformatics analysis for sequence enrichment and affinity ranking

✅ Rapid turnaround time with detailed technical support throughout the project

Whether you need antibody mimetics, target-binding peptides, or molecular probes, our platform is designed to deliver high-specificity hits that accelerate your research or drug development pipeline.

Application Scenarios

Our phage display services are suitable for a broad range of applications:

🔬 Therapeutic peptide discovery

🧬 Biomarker identification

🧫 Antimicrobial peptide screening

💊 Drug delivery targeting

🔗 Peptide-drug conjugate development (PDCs)

Customized Phage Display Library Construction

Looking for a tailored solution? We specialize in constructing custom phage display peptide libraries based on your specific research needs. Our team works closely with you to design and synthesize libraries that reflect your target binding preferences, amino acid composition, and structural features.

One-Stop Phage Display Service Workflow

Our end-to-end workflow includes:

Library design & synthesis

Biopanning (target screening)

Clone selection and sequencing

Binding affinity verification

Data analysis and reporting

From concept to candidate, we ensure high-quality and reliable results at every step.

Why KS-V Peptide?

With years of experience in synthetic peptide development and a proprietary KPDS™ Platform, KS-V Peptide stands out as a trusted partner for biotech, pharma, and academic clients worldwide.

🌍 Global client base

🧪 Robust lab infrastructure

💡 Innovative technology platform

👨🔬 Scientific consulting by peptide experts

Get Started Today

If you are looking for reliable, efficient, and innovative phage display services, KS-V Peptide is your ideal partner. Contact us to discuss your project needs and receive a customized service proposal.

👉 Visit our service page: https://www.ks-vpeptide.com/phage-display-services.html

0 notes

Text

The SICK BTF13-A1AM2020 Wire Draw Absolute Encoder is a reliable and accurate solution for measuring linear positions in industrial automation. Designed for long-lasting performance, it features a wire draw mechanism and absolute encoder technology that ensures precise position feedback, even after power loss. With easy installation and robust construction, it is ideal for use in cranes, lifting systems, and factory automation. The BTF13-A1AM2020 supports a wide measuring range and delivers consistent results in tough environments. Choose this encoder from Auto2mation for dependable position sensing in demanding applications. Perfect for enhancing productivity and machine safety.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Sick#Absolute Encoder#Encoder

0 notes

Text

Data Science Training in Kerala: Building Future-Ready Careers in a Data-Driven World

In the 21st century, data has emerged as the most valuable asset for businesses across the globe. Every click, swipe, purchase, and search generates a massive amount of information. Companies now depend on skilled professionals who can analyze, interpret, and derive actionable insights from data to maintain a competitive edge. This rising demand has made data science training in Kerala a popular and crucial stepping stone for individuals aiming to secure a thriving career in technology.

Kerala, renowned for its literacy and educational achievements, is rapidly becoming a hub for tech and data science learning. If you aspire to make a mark in this exciting field, understanding the landscape of data science and choosing the right training program is key to your success.

Why Data Science is the Career of the Future

1. Explosive Job Growth

As businesses continue to digitize, the volume of data being generated is growing exponentially. According to LinkedIn and other career platforms, data science roles are among the fastest-growing job categories worldwide. Data analysts, data engineers, and machine learning specialists are in high demand.

2. High Salaries and Career Progression

Data science professionals command some of the highest salaries in the technology sector. In India, an entry-level data scientist can earn anywhere between ₹6–10 LPA, and seasoned professionals easily cross the ₹25 LPA mark. Beyond salary, data science also offers clear paths for career advancement into leadership and strategic roles.

3. Applicability Across Industries

One of the best aspects of pursuing data science training in Kerala is the versatility it offers. Whether it's healthcare, finance, e-commerce, education, or logistics, data science skills are applicable across multiple industries.

Core Components of a Data Science Training Program

A comprehensive best data science training in Kerala should offer a well-rounded curriculum covering technical and soft skills. Here's what you should expect:

1. Mathematical and Statistical Foundations

Understanding the basics of statistics, probability, and linear algebra is crucial for data-driven decision-making and model-building.

2. Programming Skills

Python is the most popular language in data science. Training should cover:

Data manipulation with Pandas and NumPy

Data visualization using Matplotlib and Seaborn

Machine learning libraries like Scikit-Learn, TensorFlow, and PyTorch

3. Data Handling and Preprocessing

Cleaning and preparing data is a critical first step in any data science project. Knowledge of handling missing data, encoding categorical variables, and feature scaling should be emphasized.

4. Machine Learning Algorithms

From regression and classification models to clustering and dimensionality reduction techniques, a strong understanding of machine learning is non-negotiable for aspiring data scientists.

5. Big Data Technologies

Familiarity with big data ecosystems such as Hadoop, Spark, and cloud platforms like AWS, Azure, or Google Cloud can provide a significant advantage.

6. Real-World Projects

Theory is only valuable when applied. A quality training program includes live projects in areas like fraud detection, customer segmentation, recommendation systems, and predictive analytics.

7. Soft Skills and Business Acumen

Understanding the business context and being able to present data-driven insights effectively is as crucial as technical skills. Presentation, storytelling with data, and communication training are essential parts of good data science education.

Why Kerala is a Rising Hub for Data Science Education

Kerala is traditionally known for its commitment to education and innovation. With its increasing focus on IT parks, startups, and entrepreneurship, it is now becoming a promising destination for tech training as well.

IT Infrastructure Growth: Areas like Kochi (Infopark, SmartCity) and Trivandrum (Technopark) are rapidly expanding, hosting numerous tech companies.

Affordable Quality Education: Compared to other metropolitan cities, Kerala offers high-quality education at more reasonable costs.

Skilled Talent Pool: Kerala’s excellent universities and focus on STEM education mean students have a strong foundation to specialize further through courses like data science training in Kerala.

Vibrant Tech Community: Regular tech events, workshops, hackathons, and seminars help students and professionals network and stay updated on industry trends.

What to Look for When Choosing a Data Science Training Program?

When investing time and resources into data science institute in Kerala, consider the following factors:

Expert Trainers: Courses should be taught by experienced professionals, not just theorists.

Updated Curriculum: Data science is evolving rapidly; a good course must reflect current tools, trends, and technologies.

Project Work: Hands-on learning via real-world projects ensures you are job-ready upon completion.

Placement Support: Good institutes provide career guidance, resume reviews, and connections to hiring companies.

Flexible Learning Options: Depending on your schedule, options for online, hybrid, or weekend classes can be extremely beneficial.

Zoople Technologies: Leading the Future of Data Science Training in Kerala

When it comes to world-class data science training in Kerala, Zoople Technologies stands out as a leader. With a mission to bridge the gap between academic knowledge and industry demands, Zoople offers comprehensive and career-focused training that truly transforms learners into professionals.

Why Choose Zoople Technologies?

Industry-Expert Trainers: Learn from mentors who have rich experience in multinational corporations and cutting-edge tech projects.

Comprehensive Curriculum: Zoople’s program covers everything from foundational mathematics to advanced machine learning, AI, and big data technologies.

Project-Based Learning: Students work on live projects, gaining practical experience that employers value.

Strong Placement Assistance: With dedicated career support teams, Zoople helps students with mock interviews, resume preparation, and job placements.

Flexible and Modern Learning: Whether you prefer in-person, hybrid, or online classes, Zoople offers flexible formats tailored to your needs.

Vibrant Alumni Network: Connect with Zoople’s alumni community, many of whom now work with leading tech giants across India and abroad.

Choosing Zoople Technologies for your data science training in Kerala ensures that you are not just learning theoretical concepts but also gaining the practical, hands-on experience required to excel in a competitive job market.

Final Words

Data science is no longer just a buzzword; it is a career-defining opportunity for anyone passionate about technology, analytics, and innovation. As industries become increasingly data-driven, professionals with strong data science skills will be the ones leading change.

If you're serious about launching a successful career in this exciting field, enrolling in a trusted data science training in Kerala program is the first step—and Zoople Technologies is the ideal partner to guide you on that journey.

1 note

·

View note